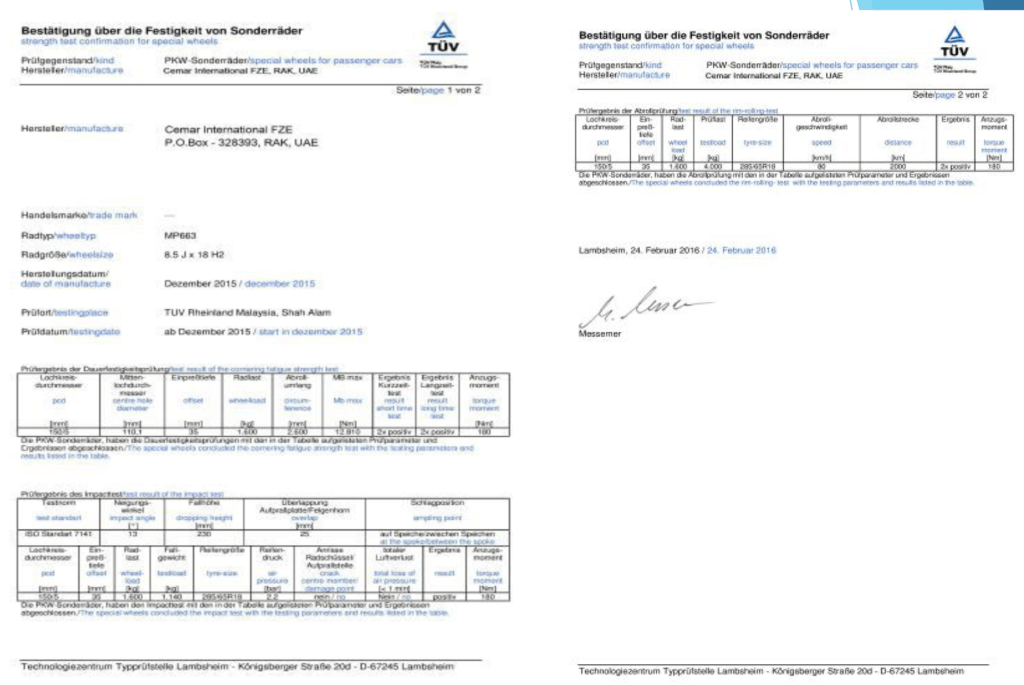

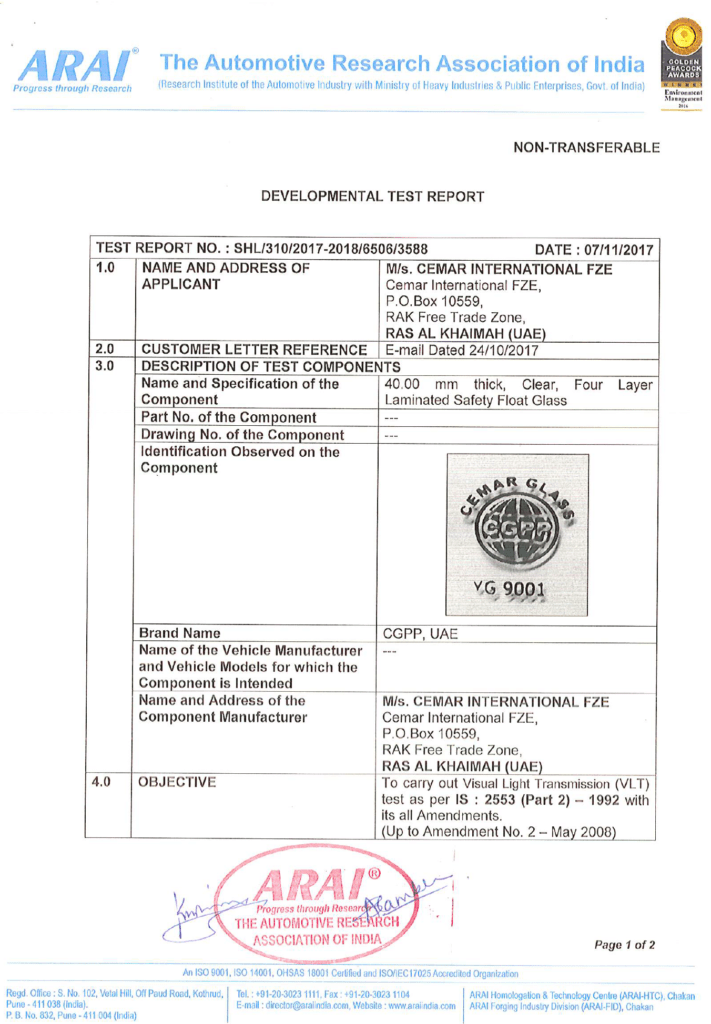

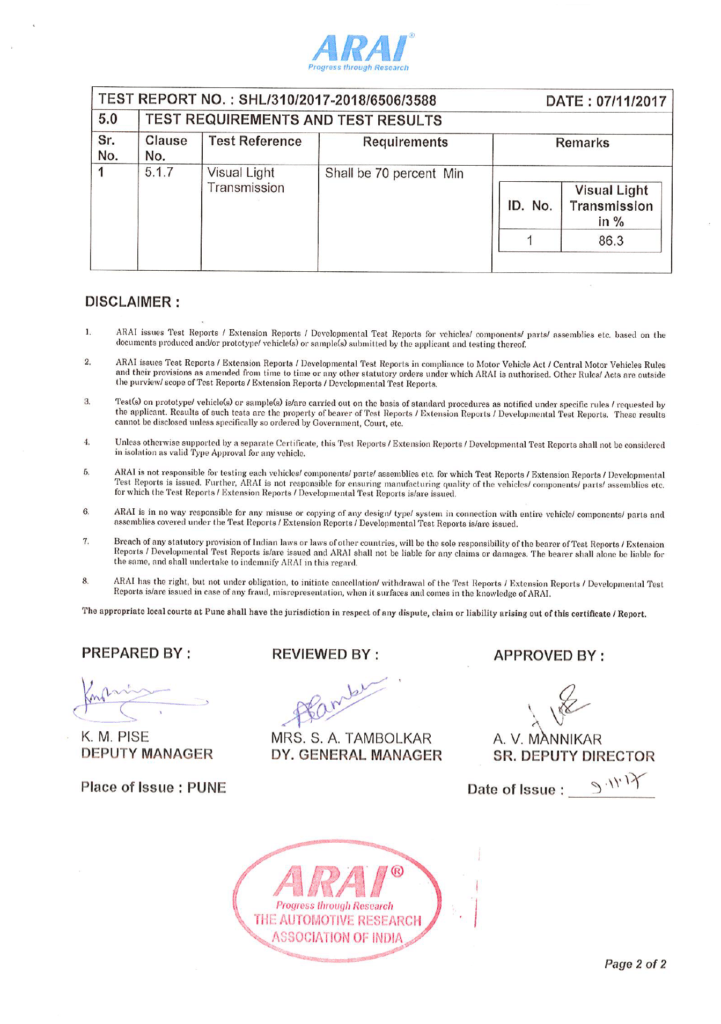

CERTIFICATIONS

OUR Material Certifications

PROTECTION LEVELS

Protection Levels

BR2

Caliber – 9mm Luger

Ammunition – FJ/RN/SC

Mass (g) – 8 ± 0.1

Test Range (m) – 5.00 ± 0.5

Bullet Velocity (m.s) – 400 ± 10

# of Strikes – 3

BR3

Caliber – .357 Magnum

Ammunition – FJ/CB/SC

Mass (g) – 10.2 ± 0.1

Test Range (m) – 5.00 ± 0.5

Bullet Velocity (m.s) – 430 ± 10

# of Strikes – 3

BR4

Caliber – .44 Magnum

Ammunition – FJ/FN/SC

Mass (g) – 15.6 ± 0.1

Test Range (m) – 5.00 ± 0.5

Bullet Velocity (m.s) – 440 ± 10

# of Strikes – 3

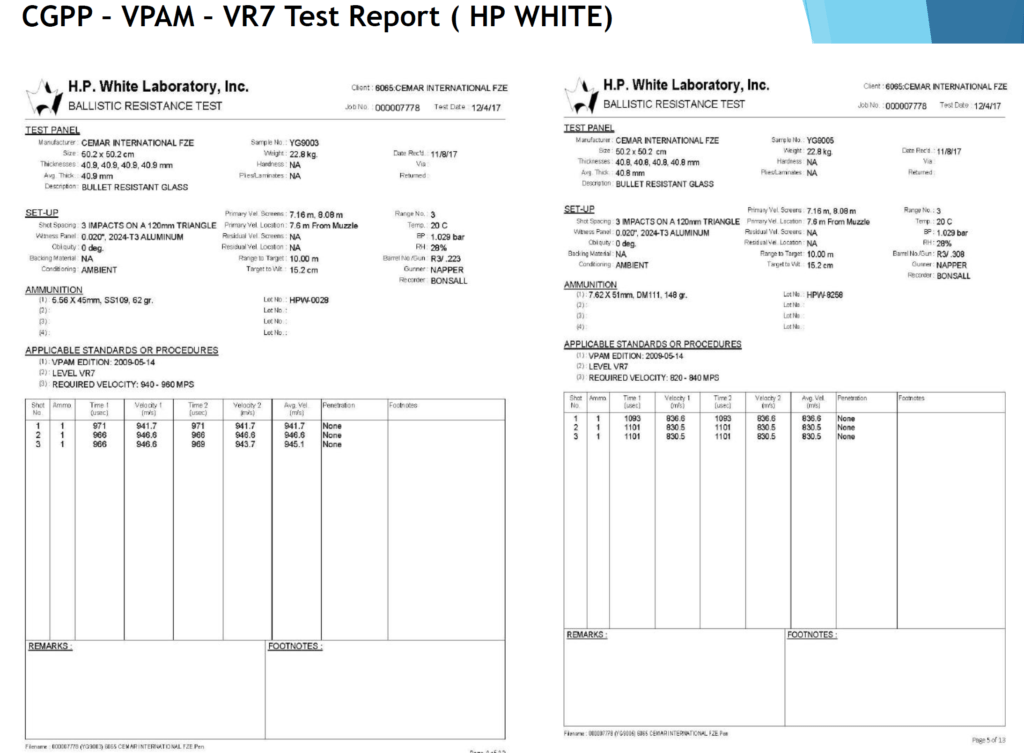

BR5

Caliber – 5.56 x 45 mm

Ammunition – FJ/PB/SC

Mass (g) – 4.0 ± 0.5

Test Range (m) – 10.00 ± 0.5

Bullet Velocity (m.s) – 950 ± 10

# of Strikes – 3

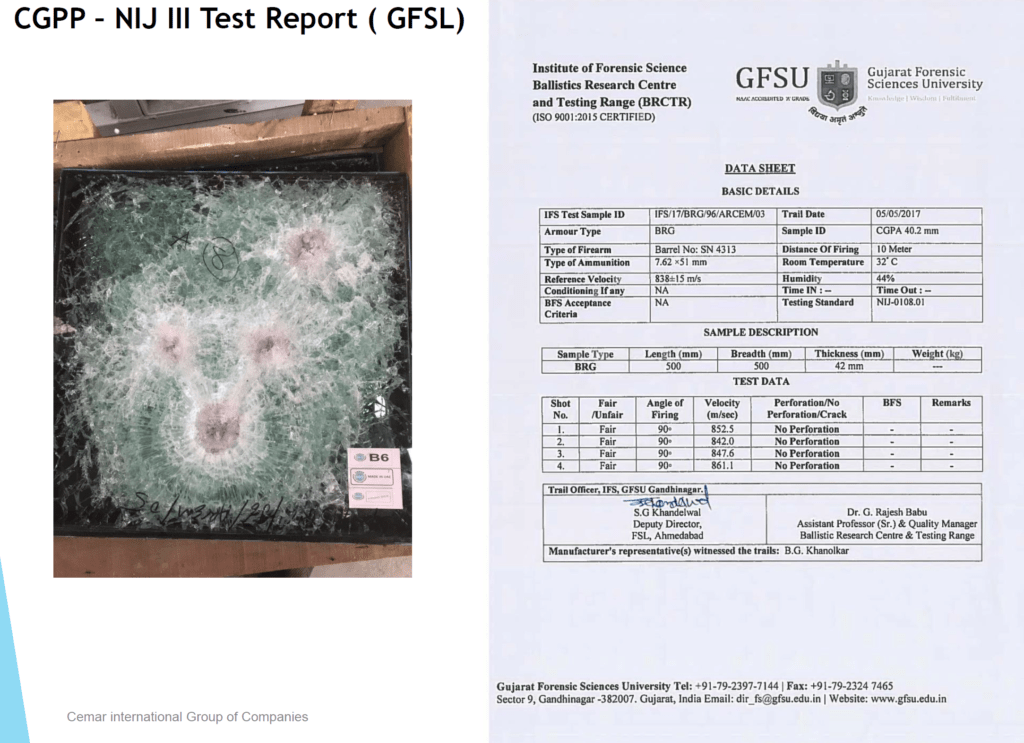

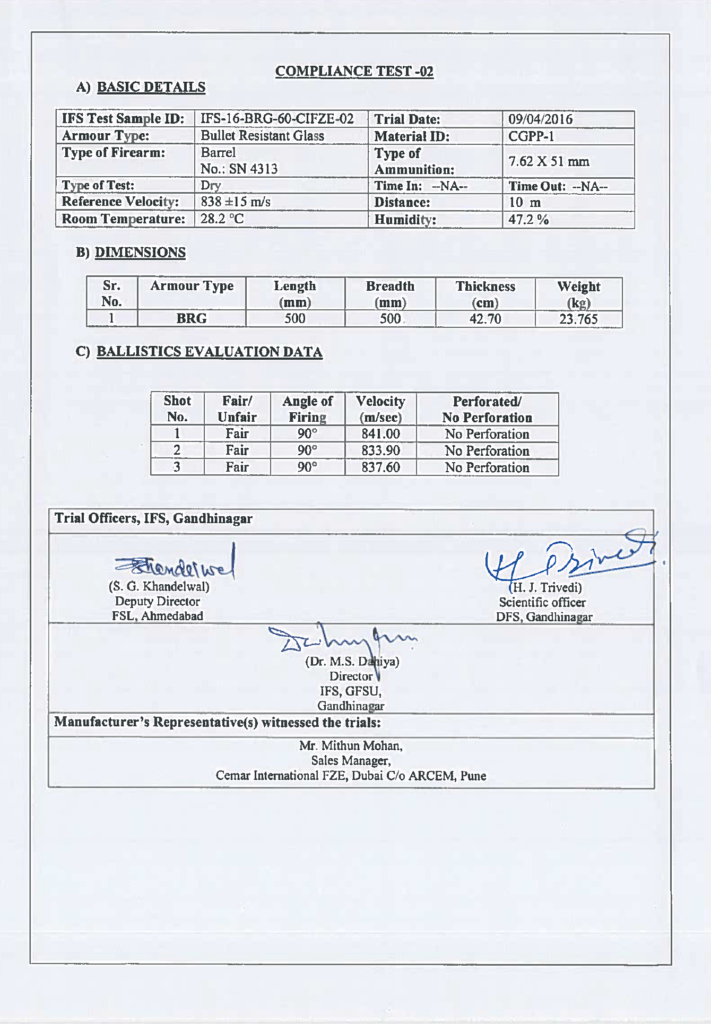

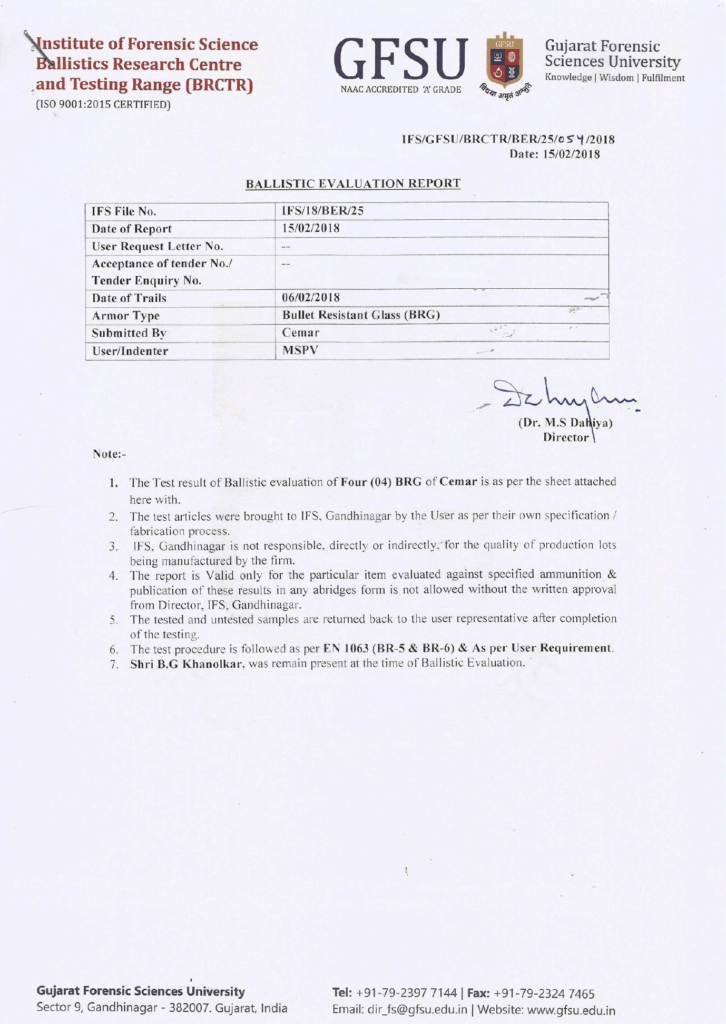

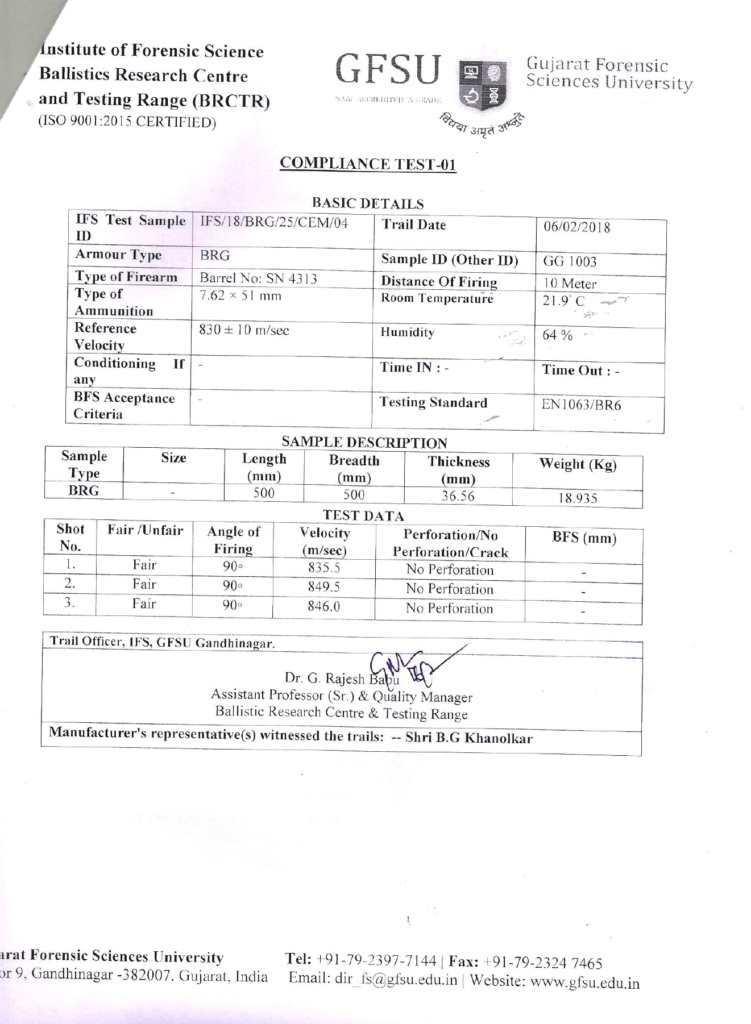

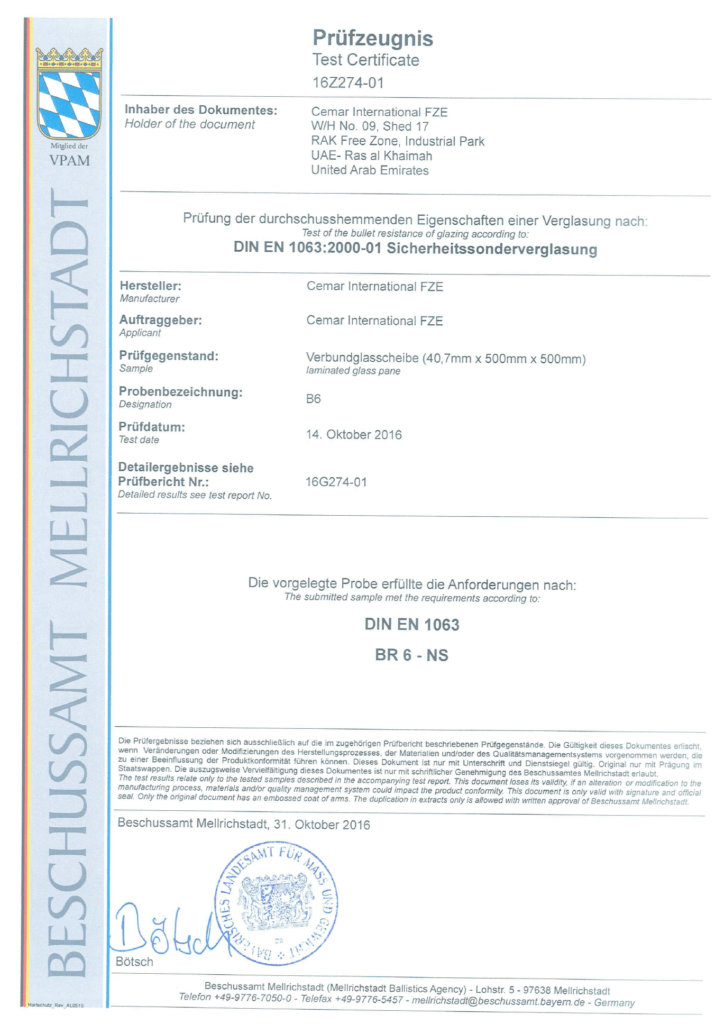

BR6

Caliber – 7.62 X 51 mm

Ammunition – FJ/PB/SC

Mass (g) – 9.5 ± 0.1

Test Range (m) – 10.00 ± 0.5

Bullet Velocity (m.s) – 830 ± 10

# of Strikes – 3

BR7

Caliber – 7.62 X 51 mm

Ammunition – FJ/PB/SC

Mass (g) – 9.5 ± 0.1

Test Range (m) – 10.00 ± 0.5

Bullet Velocity (m.s) – 830 ± 10

# of Strikes – 3

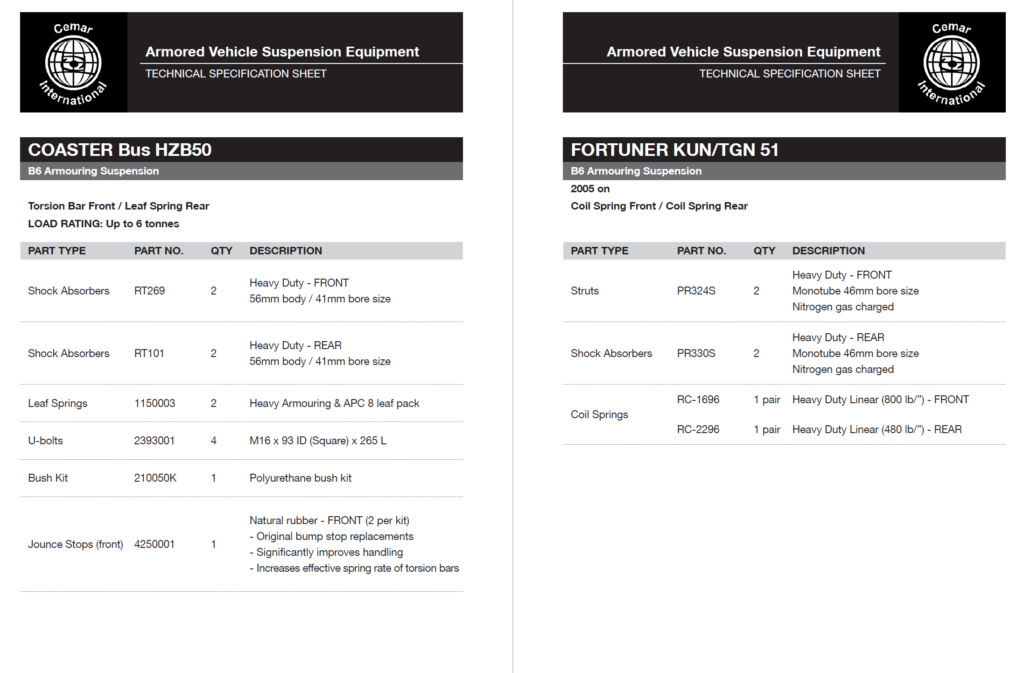

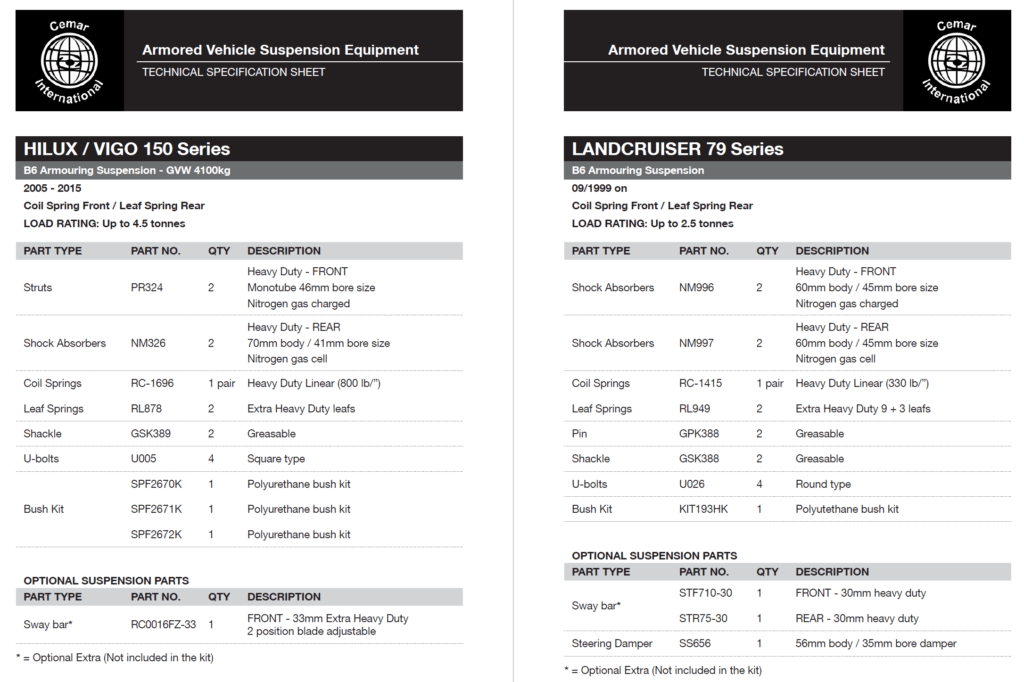

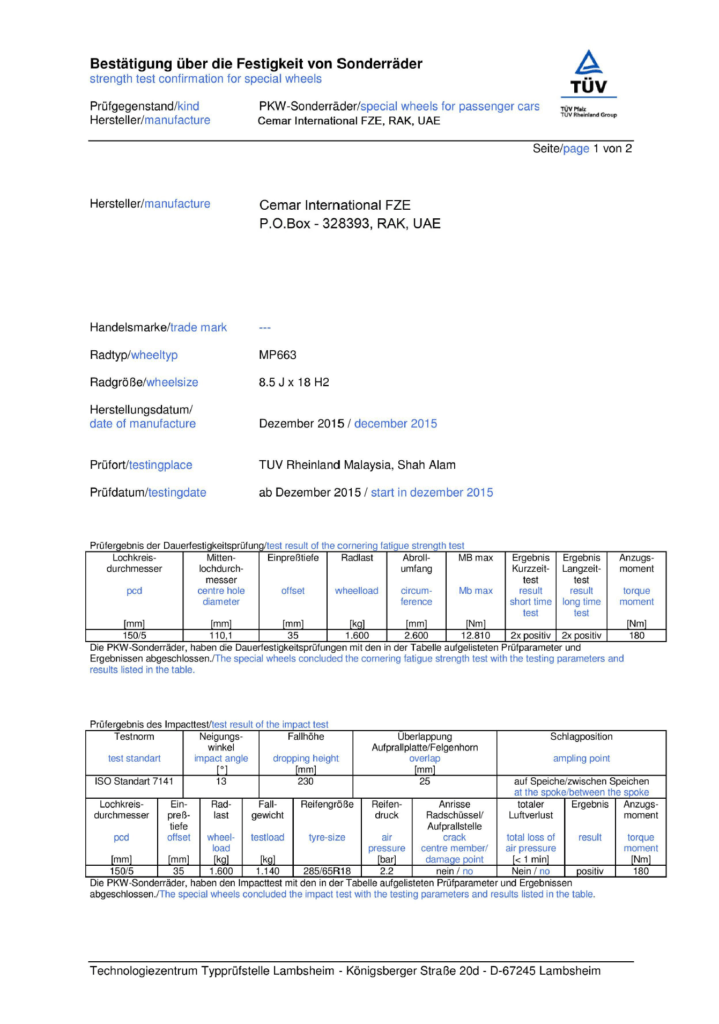

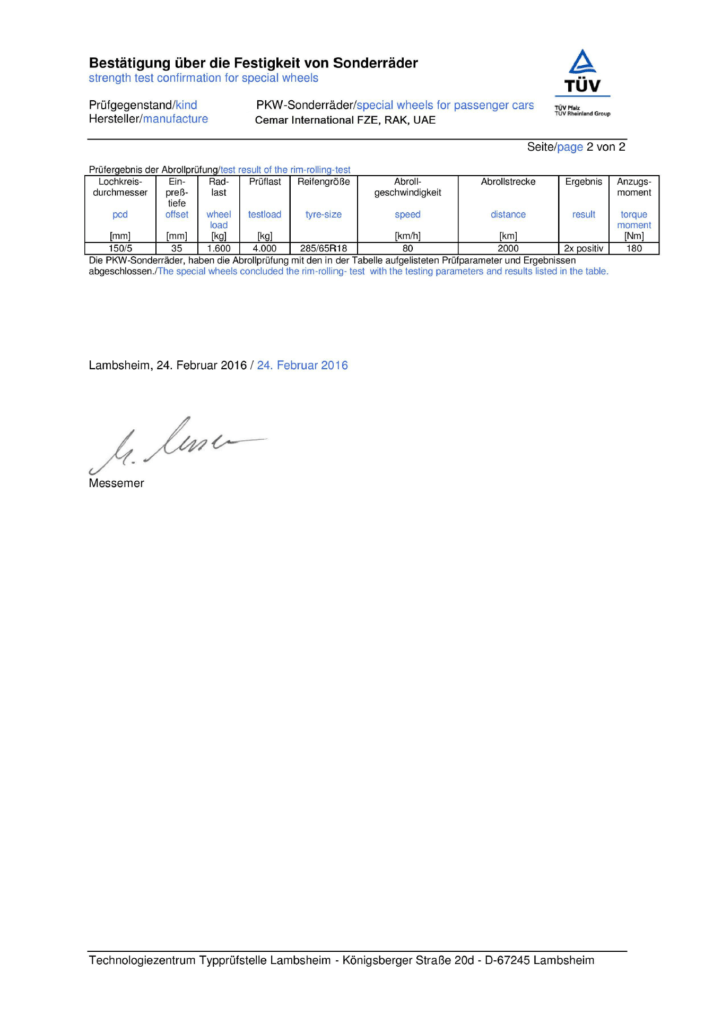

OUR PROCESS

Ballistic Standards

International ballistic standards are created to reflect the most common types of ballistic threat present in the specific geographic region. For example, certain clients may only require light armoured vehicles to protect against handguns and sub-machine guns (smaller calibre firearms), while others may require heavier armouring for their vehicle rated to defeat high powered rifle and machine gun ammunition. We offer high-end armoured solutions that offer you complete peace of mind based on your custom requirements and international standards. An armoured vehicle will not only protect you, but also allow you to escape a dangerous situation.

Our Process

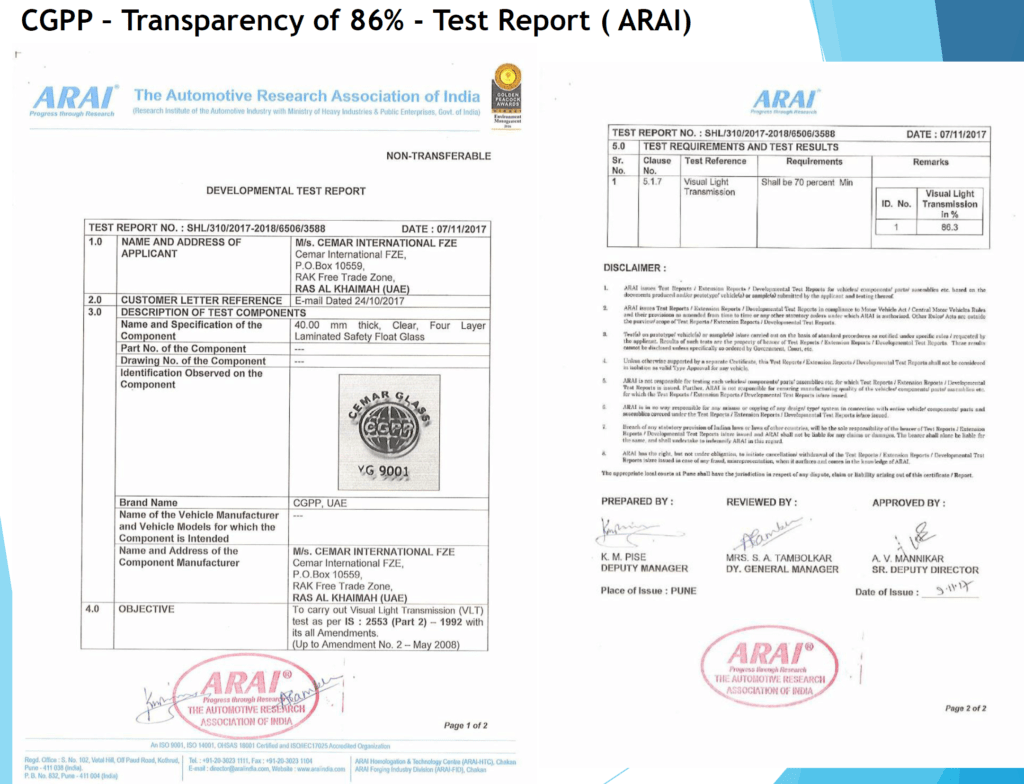

We specialize in delivering security solutions without compromising on safety, quality or passenger comfort. Two types of armoring are used in the vehicle armoring process – transparent and opaque. Transparent armor is used for the windows and consists of dense layered ballistic glass that is laminated to a tough inner spall shield of resilient polycarbonate. Opaque armor is a lightweight composite armor, high – hardened ballistic steel and other specialized ballistic materials. The vehicle is subjected to a thorough inspection to locate any previous damage before beginning the armoring process. According to the level of vehicle armor, some components are modified to guarantee maximum security and performance. Our technicians completely remove the interior of the vehicle with the utmost care to facilitate the installation of the shield. Our technicians work in the adaptations of the interiors, at the armor level, to preserve their nature. The plates are then installed, eliminating ballistic holes and ensuring maximum protection. The windows are carefully installed so that the exterior of the vehicle maintains its original appearance. Our engineering department develops vehicles and special integrations with a wide range of configurations offering solutions that guarantee the fulfillment of any requirement. Finally the vehicle is inspected to ensure that customer requirement and quality standards are met or exceeded.